Non

Non

Description

Basic Info.

| Model NO. | BY-12080CSB(QD) |

| Power | Ultrasonic |

| Model | by-20kcsb(Gy) |

| Dimensions(Wxhxd) | (L)2000mm*(W)1200mm*(H)2500mm. |

| Frequency | 20kc |

| Transport Package | Wooden Case |

| Specification | (L)2000MM*(W)1200MM*(H)2500MM. |

| Trademark | BOYI |

| Origin | China |

| HS Code | 8515809090 |

| Production Capacity | 1000 Sets/Year |

Product Description

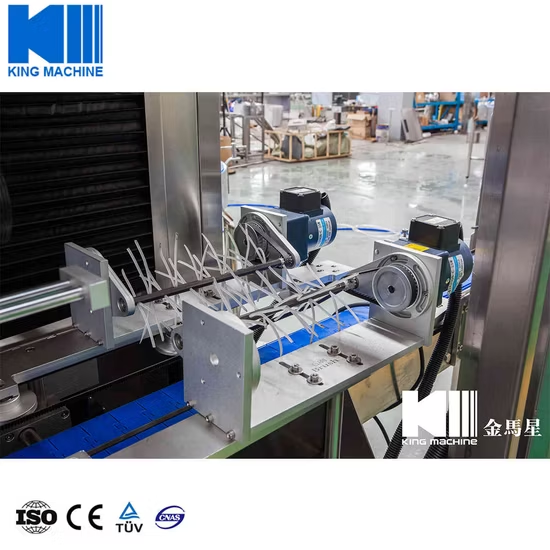

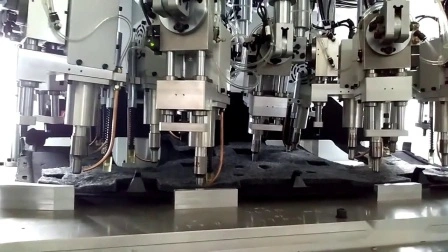

| Multi-head Ultrasonic Welding Machine Model:BY-12080CSB(QD) | |

| This equipment has been applied to ultrasonic welding of automobile coat racks and other products, with 10 welding points. | |

| Product Description | 10 sets of welding procedures can be pre-stored, and the data interface can be linked to the production line. |

| Equipped with man-machine interface, Chinese and English interface operation is more intuitive... | |

| The cooling system adopts blowing air cooling. | |

| The production cycle is 35S-45S. | |

| Man-Machine Engineering | Safety: The equipment is equipped with a protective grating and a safety baffle for scalding safety warnings |

| Authority management: The device sets the administrator and operator authority. | |

| The height of the working table is 900MM | |

| The device is started by two hands. | |

| Equipment capability | Indiscriminate operation verification (the device is protected if it does not follow standard procedures). |

| Quality traceability | Production capacity record. |

| Alarm fault code and its record. | |

| Man-Machine Interface-The visual information of the man-machine interface includes current operation steps, alarm information and solutions. | |

| IMS interactive function: support Ethernet communication, the device has a QR code scanning and identification function, the hot plate temperature, displacement, and the data can be recorded and the data needs to be pushed to the company's IMS system. (This function is customized according to customer requirements.) | |

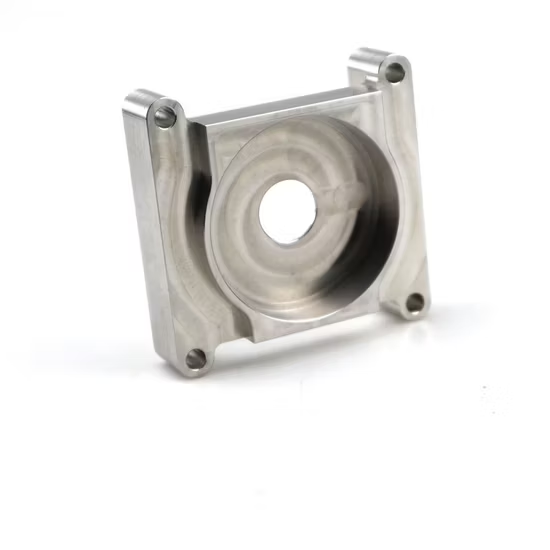

| Equipment fixture | The equipment can be independently equipped with a mold changing cart.( This item is customized according to customer) |

| Quick die change | The fixture of the equipment adopts simple, fast and reliable fixing methods such as positioning pins, without special tools. |

| The pneumatic part and sensor part of the fixture of the equipment are designed with quick plug-in. | |

| The quick mold change time is 10-15minutes. | |

| Electrical layout/Safety | The equipment tool is equipped with sensor recognition, the model selected by PLC is different from the current fixture, and an alarm is required. |

| Locking function-when the product is detecting NOK, the product is locked in this station (requires designated personnel to unlock) | |

| Equipment alarms, fault information or corresponding faults are displayed on the man-machine interface.. | |

| Control system voltage DC24. | |

| I/O- Each station I/O has a 10% margin for future expansion.. | |

| Technical Parameters | Equipment dimensions:(L)2000MM*(W)1200MM*(H)2500MM. |

| Maximum mold capacity of equipment:1200MM*(W)800MM*(H)600MM. | |

| Power : 3-phase 380V 50Hz, can be customized. | |

| Air source specifications: 4Kg/cm2-6Kg/cm2(0.4MPA-0.6MPA). | |

| Adaptable to ambient tmperature: : -5ºC~40ºC | |

| Adaptable to ambient humidity : 20%~80% | |

| The noise of the transmission part does not exceed 70 decibels | |

Next: Customed Warning Self

Our Contact

Send now